QT-120 Concrete Pipe Making Machine

QT-120 concrete pipe making machine can make 40 to 120 pieces of pipes per day as per different diameter.

QT-120 concrete pipe making machine price is from 4000 USD to 6000 USD as per the quantity of pipe moulds.

Process of Making Concrete Pipe:

- Assemble the pipe mould.

- Carry the mould to the work position and lock the mould.

- Press lower button to lower down the rotating head.

- Feed some raw material and start rotating head. Continue to feed raw mateial until it is full with the mould.

- Can add a little water at the end of pipe forming to make the pipe more smooth.

Pipes made from QT-120 Concrete Pipe Making Machine

These pipes are widely used in the farm irrigation, sewage pipe, drain pipes;

Concrete Pipe Making Machine Detailed Introduction

1. JQ350 concrete mixer

- Diameter: 1.2m

- Motor power: 5.5KW-6 or 7.5kw-4

- Weight: 350 KG

- Wall thickness: 8mm

- Bottom plate thickness: 7mm

- Function: The main function of the cement mixer is to mix and stir various materials such as cement, aggregates, and water to form uniform concrete. It achieves this by driving the mixing blades within the drum of the mixer with an electric motor, generating strong shear force and stirring force.

2. 4 Meter Belt Conveying Machine

Motor power: 1.5KW

This belt conveying machine is used to conveying the mixed raw materials into the concrete pipe making machine, this can save two labors here and improved efficiency.

3. QT-120 Concrete Pipe Making Machine

| QT-120 Concrete pipe making machine main technical parameters |

| Pipe Mould Diameter (Inside mm) |

| φ200 |

φ300 |

φ400 |

φ500 |

φ600 |

φ700 |

φ800 |

φ1000 |

| Accordingly Wall Thickness |

| 30mm |

30mm |

40mm |

50mm |

60mm |

70mm |

80mm |

100mm |

| motor Power |

18kw |

| Speed of main shaft |

45r/min |

| Reducer Rate |

1:5.8(ZQ250) |

| Molding Cycle |

5-10 min(depends on the dimension) |

| Max Pressure: |

110T |

| Productivity |

100 pieces /shift |

| Whole Weight |

1500kg(except mould) |

| Whole Dimension |

2200*2000*4150mm |

| Machine Weight: |

1.5 ton |

The vertical extrusion cement pipe manufacturing machine adopts the core mold vibration process (inner mold vibration process) of the cement pipe manufacturing machine. This process uses semi-dry-hard concrete. The inner molds are vibrated vertically and the pipe is extruded radially. The vertical core mold vibration pipe manufacturing process uses two integral pipe molds. The molds have excellent rigidity and are not prone to deformation. Only one set of molds is needed for one specification.

4. Manual Trolley

Function: used to carry the formed concrete pipe to the curing area.

Finshied Concrete Pipes

Capacity of QT-120 Concrete Pipe Making Machine

| sizes of pipe |

Piece / 8 Hour |

| φ200×1000mm |

120 |

| Φ300×1000mm |

120 |

| Φ400×1000mm |

100 |

| Φ500×1000mm |

90 |

| Φ600×1000mm |

80 |

| Φ800×1000mm |

50 |

| Φ1000×1000mm |

40 |

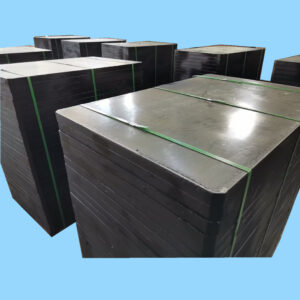

Moulds Photos

QT-120 Concrete Pipe Making Machine Packing List

| JQ350 concrete Mixer |

1 Set |

Concrete pipe making machine |

1 set |

| Belt conveying machine |

1 set |

Manual Trolley |

2 set |

Only the host pipe making machine, its total volume is around 11 Cubic meters, weight is 4 tons; can ship by Less than a container.

QT-120 Cement Pipe Making Machine FAQ

- What is the raw materials for cement pipes making?Concrete pipes can be made by using coal ash, waste residue, sand and crushed stones, along with a small amount of cement.

- How about the concrete pipe quality made from this QT-120 cement pipe making machine?The concrete pipes produced by this cement pipe manufacturing machine have excellent performance in terms of pipe wall thickness, surface smoothness, compressive strength, ease of connection and firmness, as well as anti-seepage properties. They are widely used in agricultural irrigation and drainage projects in cities.

- What is the advantages of this QT-120 cement pipe making machine ?The vertical cement pipe manufacturing machine is a very economical and practical device. It features high production efficiency and quick economic returns, making it more suitable for small factories and individual investors.

- How many concrete pipe mould are needed for this concrete pipe making machineUsually, a set of pipes of the same size is sufficient to meet the usage requirements of the machine, and customers can also choose pipes of different sizes.

For more information, contact me.

QT-120 concrete pipe making machine can make 40 to 120 pieces of pipes per day as per different diameter.

QT-120 concrete pipe making machine price is from 4000 USD to 6000 USD as per the quantity of pipe moulds.

QT-120 concrete pipe making machine can make 40 to 120 pieces of pipes per day as per different diameter.

QT-120 concrete pipe making machine price is from 4000 USD to 6000 USD as per the quantity of pipe moulds.