QTM6-25 Brick Making Machine

The mobile concrete block machine QTM6-25 Model price is 9500 USD;

The QTM6-25 mobile concrete block manufacturing machine can produce 6,800 to 8,800 8-inch hollow blocks per day.

The basic configuration requirements for the QTM6-25 mobile concrete block manufacturing machine: it requires 3 to 5 workers and an area of 1,000 to 1,500 square meters.

The technology of the QTM6-25 mobile concrete block machine has now been improved. Now it can also produce standard solid bricks and paving bricks; in the past, it could only produce hollow blocks and solid blocks.

Daily capacity of QTM6-25 Mobile Concrete Block Machine

| Size (mm) |

Qty/mould |

mould cycle (s) |

capacity per hour |

daily capacity |

| hollow 400*200*200 |

6 |

20-25 s |

850-1100 |

6800-8800 |

| hollow 400*150*200 |

7 |

20-25 s |

1000-1300 |

8000-10400 |

| hollow 400*100*200 |

18 |

20-25 s |

1200-1400 |

9600-11200 |

Each Machine of QTM6-25 Brick Making Production Line

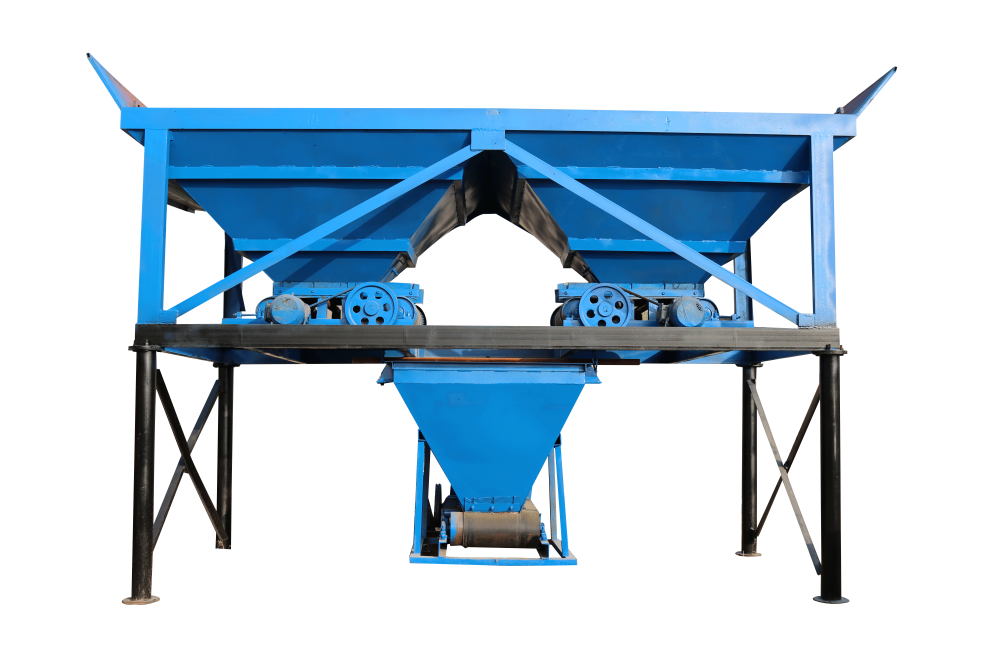

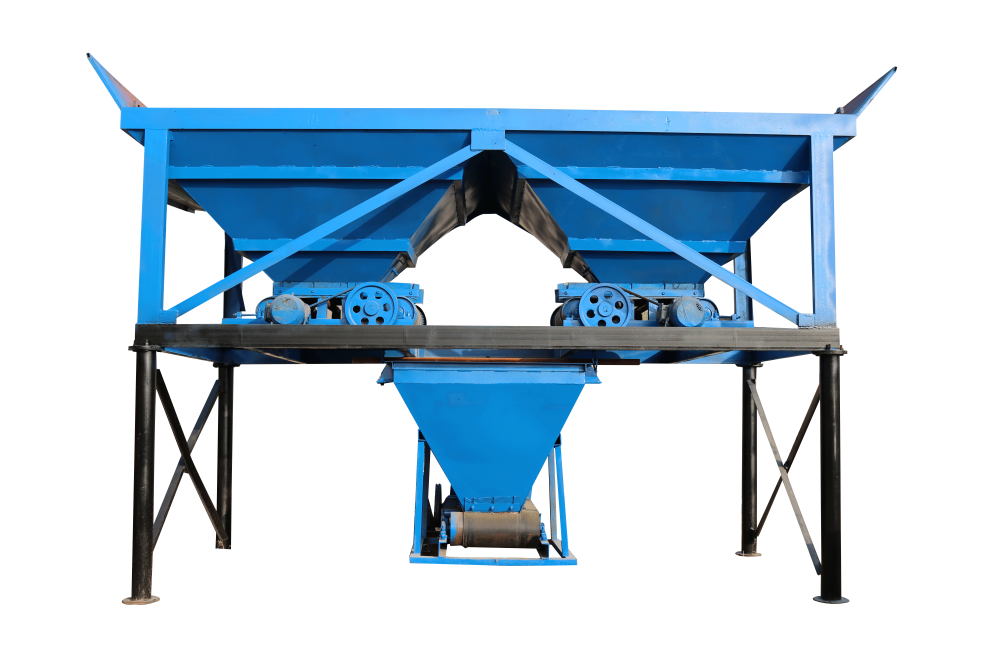

(1) PLD 1200 Batching Machine with 2 Hoppers

- Dimension: 6000*2050*2900mm

- Weight: 2800kg

- Productivity: 60m3/h

- Scale capacity: 1200L hopper

- Volume: 2*3m3

- Maxe weighing value: 3000kg

- Feeding height: 2600mm

- Power: 9kw

Working principle: First, open the door of the storage hopper through the cylinder, and load materials into the mixing hopper. When the weight of the aggregates in the mixing hopper reaches the adjustable weight of the scale, the scale lever tilts, thereby activating the travel switch mounted on the scale arm, causing its normally closed contact to open. The electrical control system then controls the action of the cylinder, closing the door of the storage hopper and stopping the material feeding, completing the weighing process. Next, use the cylinder to open the hopper of the mixing hopper as needed, and use the conveyor to transport the mixed materials that have been weighed to the mixing hopper of the mixer.

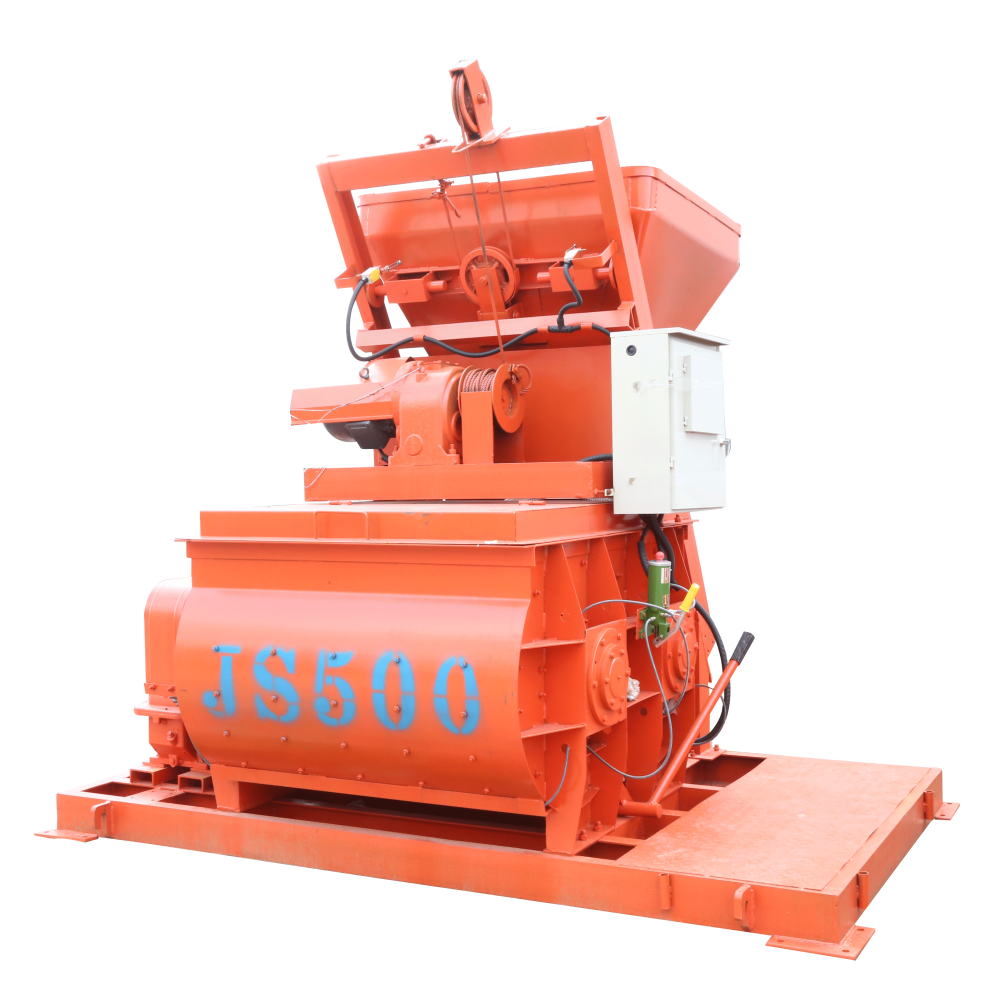

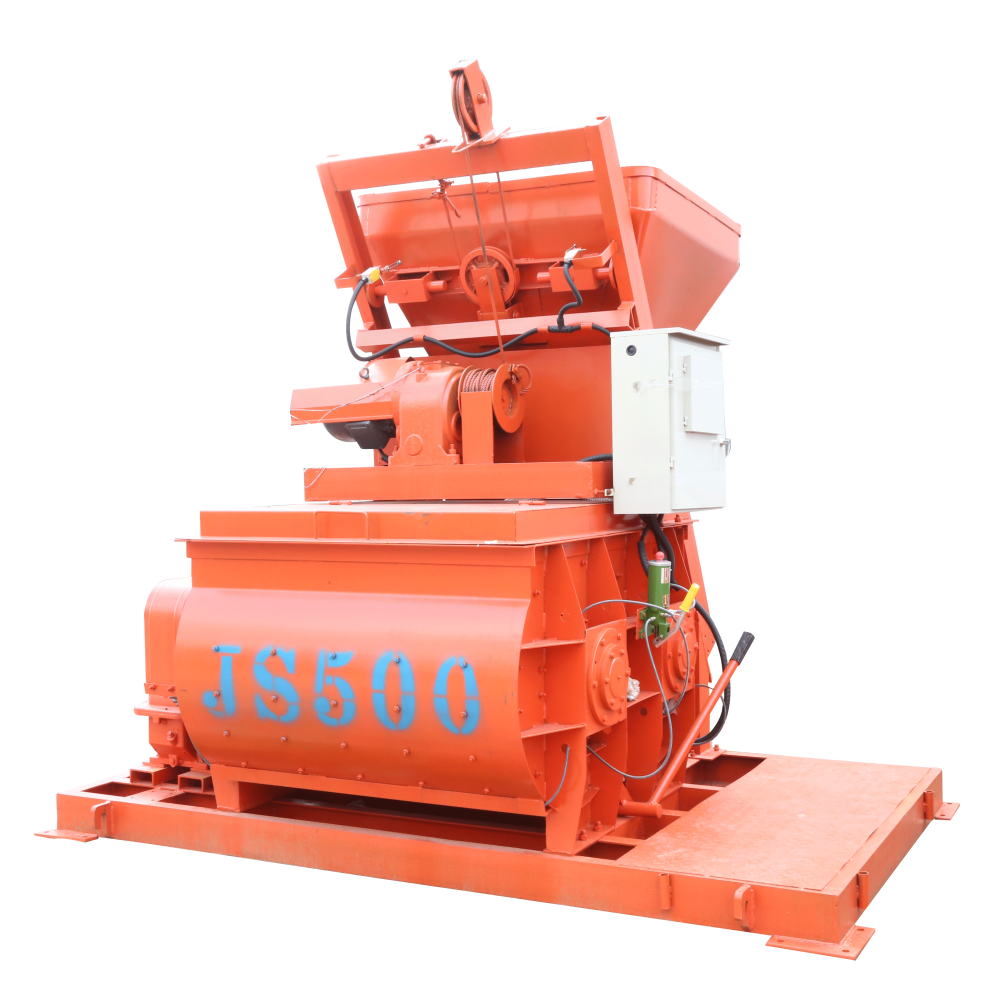

(2)JS500 Concrete Mixer

- Discharging Volume: 500L

- Charging Volume: 800L

- Capacity: 25 M3/h

- Aggarate Size: ≤60/80mm

- Working Circle: 60S

- Mixig Blade: 2*7

- Mixing Speed: 35R/M

- Mixing motor: 18.5KW

- lift motor: 5.5kw

- pump motor: 0.75kw

- Machine weight: 1500kg

- Dimension: 3030*2300*2680mm

Working Principle: Based on the centrifugal principle. When a suspension containing fine particles is at rest, due to the effect of the gravitational field, the floating particles gradually sink. The heavier the particle, the faster it sinks; conversely, particles with a density lower than that of the liquid will float up.

(3)Hopper Truck

- Hopper capacity: 0.6M3

- Load: 1T

- Engine power: 16KW

- Weight: 1100KG

- Dimension: 2620*1480*2550mm

- Dump height is customized to be suitable for QTM6-25 brick machine

(4)QTM6-25 Block machine

- Mould cycle: 25S

- Hydraulic pressure: 6-8Mpa

- Capacity: 8000-10000 pcs

- Total power: 12kw

- Voltage: 415v; 50HZ

- Diemension: 2250*2200*1750mm

- Weight: 2600kg

Working principle: The core of the mobile concrete block machine is an advanced hydraulic system. This system provides the force needed to press the concrete mixture into the molds, ensuring uniform density and strength of each block. The advanced hydraulic cylinders work in conjunction with precisely designed valves to control pressure and flow, thereby adjusting the compression degree according to different types of blocks.

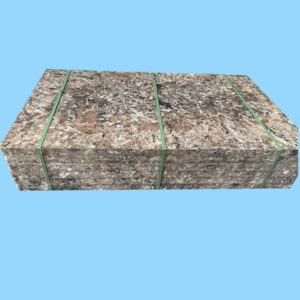

Blocks Made by QTM6-25 Brick Making Machine

For more information, contact us.

The mobile concrete block machine QTM6-25 Model price is 9500 USD;

The QTM6-25 mobile concrete block manufacturing machine can produce 6,800 to 8,800 8-inch hollow blocks per day.

The basic configuration requirements for the QTM6-25 mobile concrete block manufacturing machine: it requires 3 to 5 workers and an area of 1,000 to 1,500 square meters.

The technology of the QTM6-25 mobile concrete block machine has now been improved. Now it can also produce standard solid bricks and paving bricks; in the past, it could only produce hollow blocks and solid blocks.

The mobile concrete block machine QTM6-25 Model price is 9500 USD;

The QTM6-25 mobile concrete block manufacturing machine can produce 6,800 to 8,800 8-inch hollow blocks per day.

The basic configuration requirements for the QTM6-25 mobile concrete block manufacturing machine: it requires 3 to 5 workers and an area of 1,000 to 1,500 square meters.

The technology of the QTM6-25 mobile concrete block machine has now been improved. Now it can also produce standard solid bricks and paving bricks; in the past, it could only produce hollow blocks and solid blocks.