Hydraulic Soil – Clay brick Making Machine

The QTS2-25 clay brick making machine can make two pieces of bricks per mould at 25 seconds per circle, so its theoretical daily productivity is 2304 pieces;

The QTS2-25 clay brick machine can also be installed into a simple production line by adding a soil crusher, soil screening machine, belt conveyor and concrete mixer. The hydraulic pressure of the QTS2-25 soil brick-making machine can reach 16 to 25 megapascals and is adjustable. Therefore, the bricks produced by this brick-making machine have a high density and excellent quality.

Main parameters of QTS2-25 Soil brick making machine

| (1) |

Dimension of host machine |

1600*820*1700mm |

(3) |

Weight |

400kg |

| (2) |

Moulding period |

20-25 s |

(4) |

Daily productivity |

2304 pieces |

| (3) |

Host machine power |

7.5kw |

(5) |

Diesel engine |

12 HP |

FAQ about QTS2-25 Clay brick-making machine

(1) How to operate this clay brick machine

Operating this soil brick machine is very simple. Just put the raw materials into the brick mold, cover the press head, pull the hydraulic tank handle to a certain pressure, open the press head, pull the hydraulic handle again to push out the formed bricks, and then transport them to the curing area.

(2) How many workers are needed for this soil brick machine

Three workers are okay for operating the soil brick machine, one worker operates the concrete mixer, feeds raw materials into the mixer and discharges well-mixed raw materials onto the belt conveying machine; the other worker operates the host soil brick machine, and one worker takes formed bricks to the curing area.

(3) What are the advantages of this QTS2-25 soil brick machine

- This soil brick-making machine is a fixed-type clay brick-making machine of the Sal brand. It can be equipped with an oil mill and a sand-oil screening machine, thus forming a semi-automatic brick-making production line.

- This QTS2-25 type hydraulic brick-making machine is extremely affordable in price and has a low investment cost, making it highly suitable for small businesses. Therefore, it is applicable not only for household use but also for commercial purposes.

- The QTS2-25 manual brick-making machine does not require a brick pallets, which means it can save some costs compared to concrete block-making machines.

- This machine is easy to operate.

- The QTS2-25 type automatic brick-making machine can produce 2 bricks per mold. Therefore, sometimes customers may wish to reduce the cost of molds. In such cases, the brick molds can be designed to produce two different types of bricks per mold, but their sizes must meet the requirements.

- When the QTS2-25 brick forming machine is equipped with a diesel engine, it can be moved to any area without electricity for use.

4. Why say the QTS2-25 soil brick machine is ecological?

Because the raw materials used in this kind of brick making machine are soil and gypsum, and its shaping method is merely achieved through hydraulic pressing, no other chemical materials need to be added.

5. QTS1-25 Diesel or Electrical power clay brick-making machine

The QTS1-25 clay brick-making machine is to make 1 piece of brick per time, this model is cheaper than the TS2-25 clay brick machine, but it is fit for some clients who only have one or two workers.

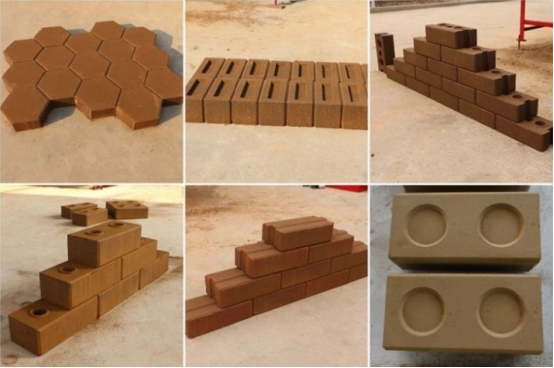

6. The clay bricks that are produced by the QTS2-25 clay brick-making machine.

Moulds of QTS2-25 Brick Making Machine

We can manufacture various different molds according to the requirements of our customers. The high-temperature quenching and carburizing treatment at 900 degrees Celsius can make the molds more sturdy and durable, with a longer service life. The cutting is carried out using wire cutting technology, ensuring that the mold shape is standard and the size is precise. After heat treatment and carburizing process, the hard molecular structure changes, increasing the strength and hardness, making it more wear-resistant. After positioning processing and milling technology treatment, the surface of the mold becomes smooth and flat, with more precise dimensions. This mold can be used approximately 100,000 times.

The QTS2-25 clay brick making machine can make two pieces of bricks per mould at 25 seconds per circle, so its theoretical daily productivity is 2304 pieces;

The QTS2-25 clay brick machine can also be installed into a simple production line by adding a soil crusher, soil screening machine, belt conveyor and concrete mixer. The hydraulic pressure of the QTS2-25 soil brick-making machine can reach 16 to 25 megapascals and is adjustable. Therefore, the bricks produced by this brick-making machine have a high density and excellent quality.

Main parameters of QTS2-25 Soil brick making machine

The QTS2-25 clay brick making machine can make two pieces of bricks per mould at 25 seconds per circle, so its theoretical daily productivity is 2304 pieces;

The QTS2-25 clay brick machine can also be installed into a simple production line by adding a soil crusher, soil screening machine, belt conveyor and concrete mixer. The hydraulic pressure of the QTS2-25 soil brick-making machine can reach 16 to 25 megapascals and is adjustable. Therefore, the bricks produced by this brick-making machine have a high density and excellent quality.

Main parameters of QTS2-25 Soil brick making machine