Small Mobile Block Machine- QTM2-45/QTM4-45/QTM4-40

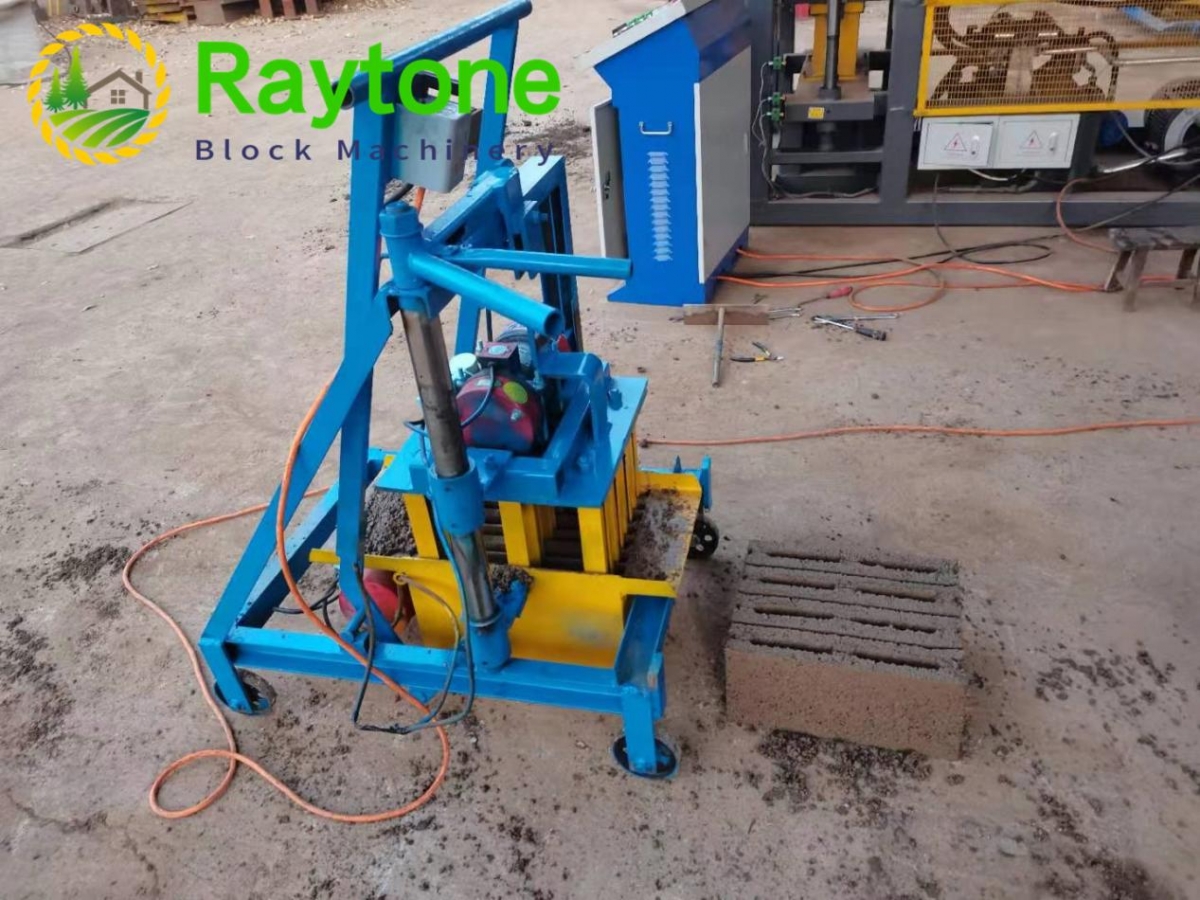

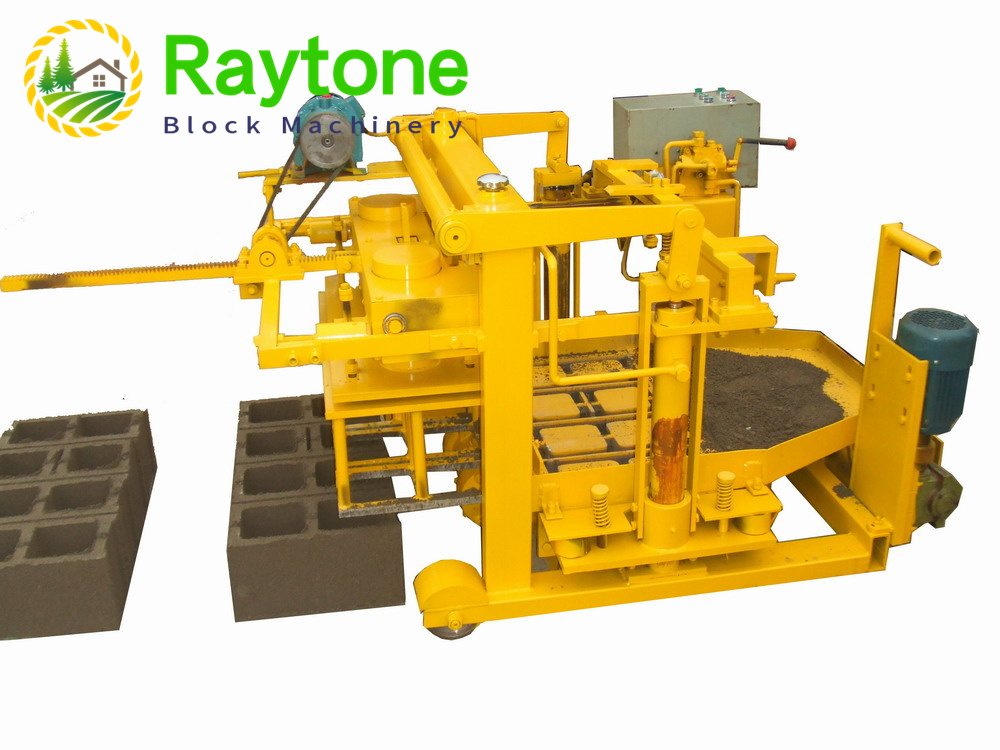

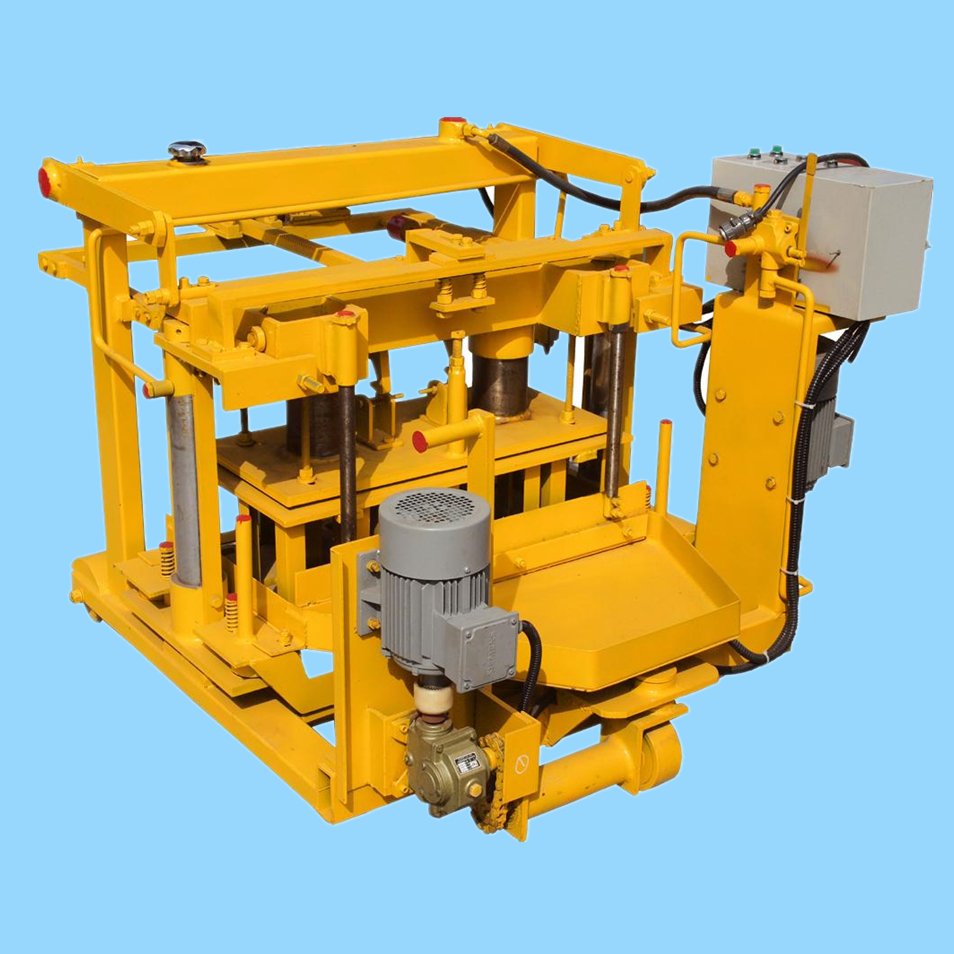

Mobile block making machine is able to make many different concrete block on concrete floor without brick pallet.

The mobile block manufacturing machine can only produce hollow blocks or solid bricks, but cannot produce paving bricks or interlocking bricks. This is because the height of the blocks is limited by the vibrator installed on the side of the bottom mold.

The following is to introduce the three models mobile block making machine separately.

(1) QTM2-45 Small Mobile Block Machine

| QTM2-45 Small Mobile Block Machine main technical parameters |

| (1) |

Dimension of host machine |

920*800*1260mm |

(4) |

Host machine power |

1.5kw |

| (2) |

Moulding period |

40-50s |

(5) |

machine weight |

220KG |

| (3) |

Voltage |

380V/415V |

|

|

|

| Productivity |

|

Size(L*W*H) |

Pieces /Mould |

Pieces / Hr |

Pieces/ 8 Hr |

Pieces /month |

| (2) |

400*200*200 |

2 |

120 |

960 |

28800 |

| (4) |

400*100*200 |

3 |

180 |

1440 |

43200 |

Main Advantages :

- Small investment, good choice for a new business.

- Small scale, do not need big space.

- Hydraulic demoulding and electrical moving, reducing labor.

- No need for pallets, can save a lot of money.

- Pushing mold by electrical motor

(2) QTM4-45 Small Mobile Block Machine

| The QTM4-45 Small Mobile Block Machine Main Technical Parameters |

| (1) |

Dimension of host machine |

1350*1300*1650mm |

(5) |

Host machine power |

6.7kw |

| (2) |

Moulding period |

30-40s |

(6) |

Vibration force |

30KN |

| (3) |

Voltage |

380V/415V |

(7) |

Mixer model |

JQ350 |

| (4) |

Weight of the host machine |

0.8T |

|

|

|

| productivity |

|

Size(L*W*H) |

Pieces /Mould |

Pieces / Hr |

Pieces/ 8 Hr |

Pieces /month |

| (1) |

400*250*200 |

3 |

180 |

1440 |

43200 |

| (2) |

400*200*200 |

4 |

240 |

1920 |

57600 |

| (3) |

400*150*200 |

5 |

300 |

2400 |

72000 |

| (4) |

400*100*200 |

7 |

420 |

3360 |

100800 |

Main Advantages:

- Using ultra-strong steel and special welding techniques, it is extremely sturdy and durable, with excellent vibration resistance performance.

- By using imported electrical equipment, sealing components and hydraulic components, such as Siemens motors, Siemens PLCs, Mitsubishi PLCs or well-known Chinese brands of motors, switches, etc., the overall performance of the equipment becomes stable and reliable.

- Our company specializes in transmission technology, which is one of the key technologies for brick-making machines. It can enhance production efficiency, increase output and boost the quantity of bricks.

(3) QTM4-40 Small Mobile Block Machine

| The QTM4-40 Small Mobile Block Machine main technical parameters |

| (1) |

Dimension of host machine |

1800*1400*1100mm |

(5) |

Host machine power |

6.7kw |

| (2) |

Moulding period |

30-40s |

(6) |

Vibration force |

35KN |

| (3) |

Voltage |

380V/415V |

(7) |

Mixer model |

JQ350 |

| (4) |

Weight of the host machine |

0.8T |

|

|

|

| production capacity |

|

Size(L*W*H) |

Pieces /Mould |

Pieces / Hr |

Pieces/ 8 Hr |

Pieces /month |

| (1) |

400*250*200 |

3 |

270-360 |

2160-2880 |

64800-86400 |

| (2) |

400*200*200 |

4 |

360-480 |

2880-3840 |

86400-115200 |

| (3) |

400*150*200 |

5 |

450-600 |

3600-4800 |

108000-144000 |

| (4) |

400*100*200 |

7 |

630-840 |

5040-6720 |

151200-201600 |

Main Advantages:

- The vibration of the mold can produce a powerful vibration effect with extremely low power consumption. By using hydraulic pressure, the raw materials can be fully filled and compacted.

- It has small dimension, but with low energy consumption and can be operated easily.

- It is highly efficient. The output is quite big. Its capacity can be compared with that of larger hydraulic machine.

- It can walk freely on concrete surface, both automatically and manually, also move forward or backward.

- There is no need to install. It can work after connecting with power.

- It doesn’t need pallet, so it can save investment.

- Saving labour: Two persons are needed in all. 1 for machine operation, and the other material mixing.

For the QTM4-40 Mobile block-making machine, can automatically walk forwards, backward, and turn around by electric, and can also be moved by hand pushing, its hydraulic components are from a Taiwan brand, the quality can be guaranteed.

(4) Brick Types

It can only produce hollow blocks or solid bricks, but cannot produce paving bricks or interlocking bricks.

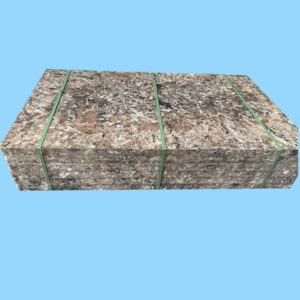

(5) Our Moulds

900 degrees celsius high temperature heat treatment carburizing heat treatment makes the mould much more strong and durability, longer life.Cutting uses wire cutting to make the mold standard in shape and accurate in size. After heat treatment and carburizing technology, the rigid molecular structure is changed, the strength and hardness are increased, and it is more wear-resistant. After positioning processing and milling machine technology, the surface of the mold is smooth and smooth, and the dimensions are more accurate. The mould can be used around 100 thousand times.

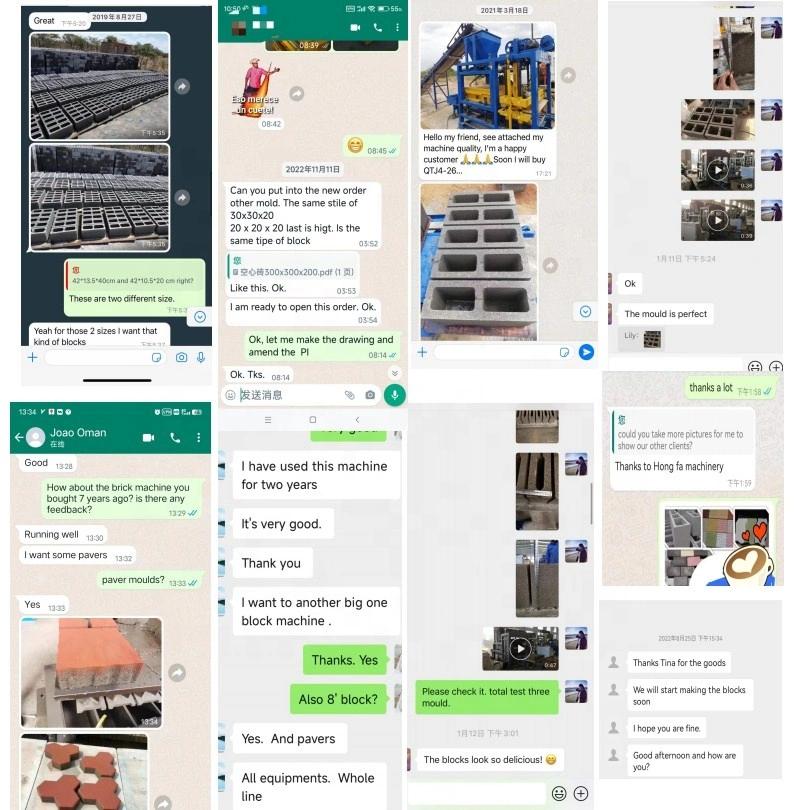

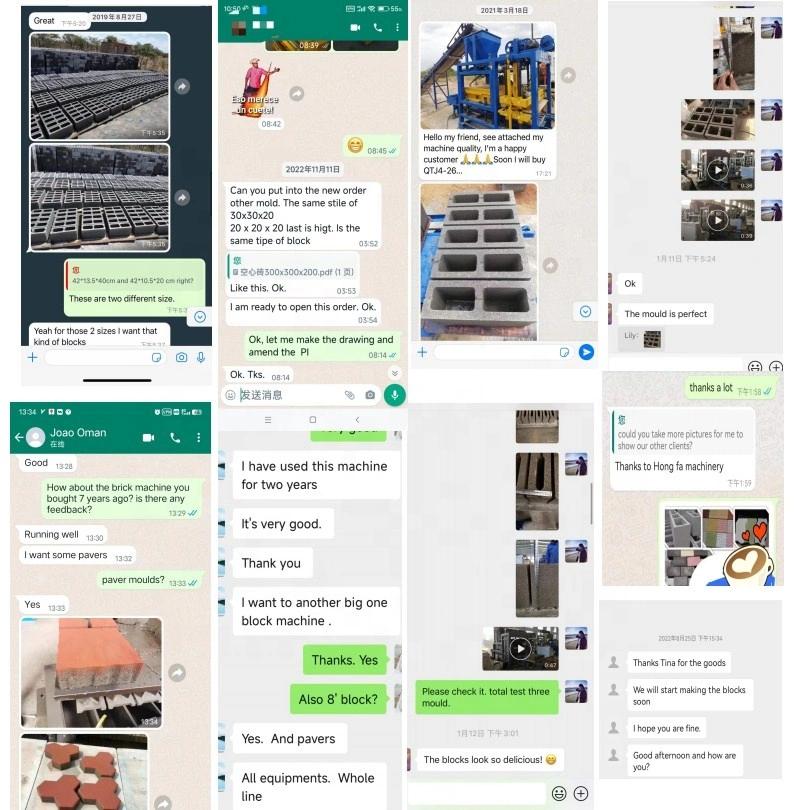

(6)Our Customers

Our brick-making machine customers are distributed all over the world. Among them, the clients from Africa account for a relatively large proportion. Many customers have given us positive feedback. With our excellent product quality, professional and meticulous service, and honest attitude, we have gained the trust of many customers. We maintain good and stable cooperative relationships with many clients, becoming inseparable partners and even friends. Choose us, you can rest easy!

(7) Shipping and Packing

We can package the machines according to your requirements. Whether it’s a plywood box or an iron frame, we can use either. Each machine will be wrapped in plastic film to reduce wear and tear. Our on-time delivery rate is 100%.

Mobile block making machine is able to make many different concrete block on concrete floor without brick pallet.

The mobile block manufacturing machine can only produce hollow blocks or solid bricks, but cannot produce paving bricks or interlocking bricks. This is because the height of the blocks is limited by the vibrator installed on the side of the bottom mold.

The following is to introduce the three models mobile block making machine separately.

Mobile block making machine is able to make many different concrete block on concrete floor without brick pallet.

The mobile block manufacturing machine can only produce hollow blocks or solid bricks, but cannot produce paving bricks or interlocking bricks. This is because the height of the blocks is limited by the vibrator installed on the side of the bottom mold.

The following is to introduce the three models mobile block making machine separately.