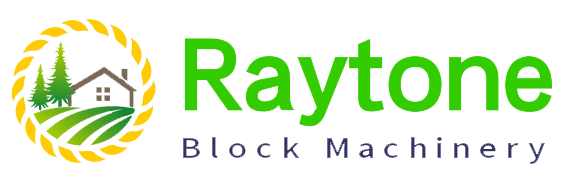

Simple Automatic Concrete Block Making Machine QT4-18 Model

The production capacity of the QT4-18 brick-making machine is 6,400 8-inch hollow bricks per day (8 hours); the price range of the QT4-18 automatic block machine

production line is from $16,100 to $29,300. The exact price will be determined based on the customer’s requirements, the quantity of molds and pallets.  The basic requirements for starting the production of the QT4-18 automatic brick-making machine production line:

The following information for the QT4-18 brick-making machine is provided for reference only. The actual production data in the field may vary due to factors such as

different raw materials.

The basic requirements for starting the production of the QT4-18 automatic brick-making machine production line:

The following information for the QT4-18 brick-making machine is provided for reference only. The actual production data in the field may vary due to factors such as

different raw materials.

QT4-18 brick making line packing list:

Note: The specific configuration should be determined according to the customer’s requirements.  Detailed Introduction of each single machine from QT4-18 Automatic Concrete Block Machine Line (1) Concrete Mixer for QT4-18 brick machine line

Model: JQ500 Concrete Mixer

Power: 11KW-4 or 7.5KW-6

Input Capacity: 800L

Output Capacity:500L

Size:1.5(L)*1.5(W)*1.4(H)m

Weight: 750kg

Barrel height: 60cm

Barrel thickness: 8mm

Bottom thickness: 7mm

Detailed Introduction of each single machine from QT4-18 Automatic Concrete Block Machine Line (1) Concrete Mixer for QT4-18 brick machine line

Model: JQ500 Concrete Mixer

Power: 11KW-4 or 7.5KW-6

Input Capacity: 800L

Output Capacity:500L

Size:1.5(L)*1.5(W)*1.4(H)m

Weight: 750kg

Barrel height: 60cm

Barrel thickness: 8mm

Bottom thickness: 7mm

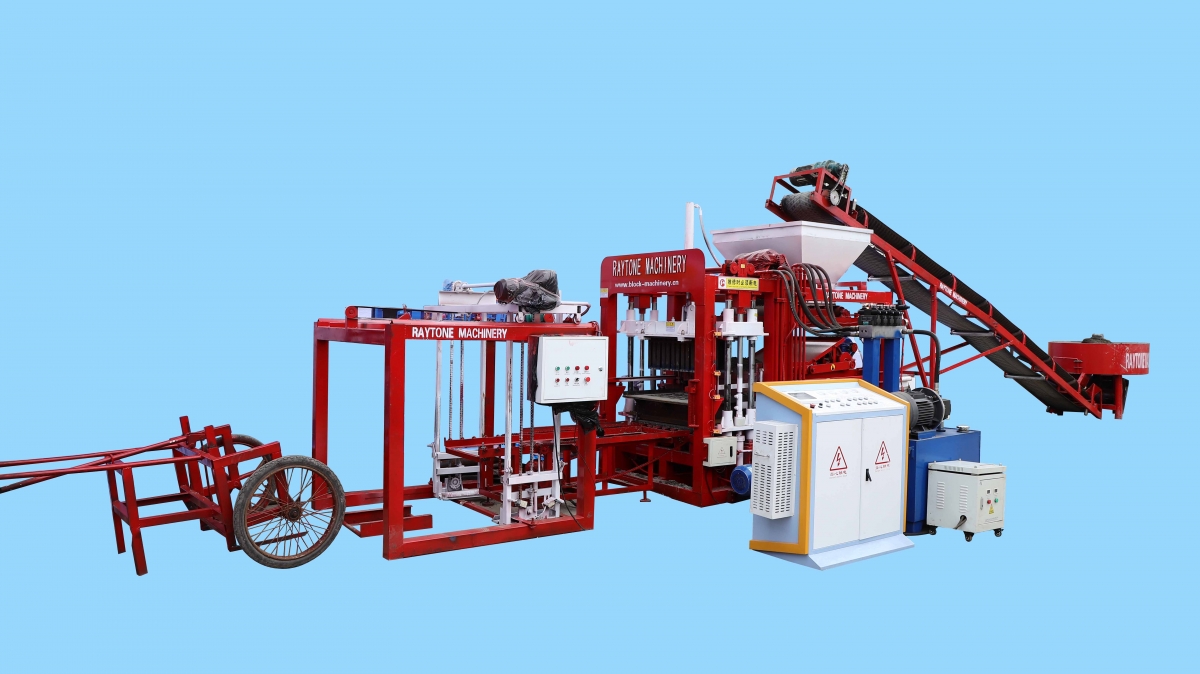

(2) Belt Conveying Machine for QT4-18 Brick Making Machine line

Model: 6M Belt Conveyor

Power: 1.5KW

Belt Width: 500mm

Weight:550kg

Client can also choose 8 Meters length for the block machine as per land area. RAYTONE block machine manufacture is using chain type rotating system instead of triangle belts for rotating the belts. It has long life and easy to maintain.

(2) Belt Conveying Machine for QT4-18 Brick Making Machine line

Model: 6M Belt Conveyor

Power: 1.5KW

Belt Width: 500mm

Weight:550kg

Client can also choose 8 Meters length for the block machine as per land area. RAYTONE block machine manufacture is using chain type rotating system instead of triangle belts for rotating the belts. It has long life and easy to maintain.  (3)Brick Pallet Feeding Machine

For QT4-18 Brick Making line. Brick Pallet Feeder Connected with host brick machine; RAYTONE block machine manufacture modified this feeding machine by making it to be a long steel plate to push the pallet, instead of two hooks at two ends, this can protect the brick pallet from damage (4)Model: QT4-18 Host Brick Machine

Size:3740(L)×2250(W)×2450(H)mm

Machine Weight:4000kg

host brick Machine power: 25KW

Motors power List:

① Hydraulic Station Motor: 11 KW

② Vibrator Motor: 5.5KW*2=11KW

③ Material Discharge Motor: 1.5KW

④ Material Distributor Motor: 1.5KW

Moulding Period 15-20 S

Vibration Force: 50-65KN

Diesel Generator Capacity: 50KVA

RAYTONE block machine manufacture is using 11KW motor for hydraulic station instead of the normal 7.5KW motor, this gives the bricks more pressure on pressing.

(3)Brick Pallet Feeding Machine

For QT4-18 Brick Making line. Brick Pallet Feeder Connected with host brick machine; RAYTONE block machine manufacture modified this feeding machine by making it to be a long steel plate to push the pallet, instead of two hooks at two ends, this can protect the brick pallet from damage (4)Model: QT4-18 Host Brick Machine

Size:3740(L)×2250(W)×2450(H)mm

Machine Weight:4000kg

host brick Machine power: 25KW

Motors power List:

① Hydraulic Station Motor: 11 KW

② Vibrator Motor: 5.5KW*2=11KW

③ Material Discharge Motor: 1.5KW

④ Material Distributor Motor: 1.5KW

Moulding Period 15-20 S

Vibration Force: 50-65KN

Diesel Generator Capacity: 50KVA

RAYTONE block machine manufacture is using 11KW motor for hydraulic station instead of the normal 7.5KW motor, this gives the bricks more pressure on pressing.  (5) PLC for QT4-18 Block Making Machine

PLC is an advanced microcomputer system, Automatic fault diagnosis, procedure is interlocked, can ensure every motion of the block machine fluently and in high efficiency.

The Siemens brand PLC and touch screen is optional. The Electrical panel is using Schneider breaker and China top brand electronic elements like Delixi or CHNT

brand electromagnetic switch as standard configuration, , having a reliable performance and low fault rate. We also equipped the frequency converter to make the electronic parts work at a safe condition.The setting of every machine motion can be done via the touch screen, perfect human-machine communicating system.

And there is also a standby software as backup.

(5) PLC for QT4-18 Block Making Machine

PLC is an advanced microcomputer system, Automatic fault diagnosis, procedure is interlocked, can ensure every motion of the block machine fluently and in high efficiency.

The Siemens brand PLC and touch screen is optional. The Electrical panel is using Schneider breaker and China top brand electronic elements like Delixi or CHNT

brand electromagnetic switch as standard configuration, , having a reliable performance and low fault rate. We also equipped the frequency converter to make the electronic parts work at a safe condition.The setting of every machine motion can be done via the touch screen, perfect human-machine communicating system.

And there is also a standby software as backup.

(6) Hydraulic Station for QT4-18 Block Machine line

The electromagnetic valve is a unique proportional valve multi-channel control system, all-round adjustment of any action, so that the machine is running more reliable and

sensitive, it is made from Taiwan CYLCA brand.

(6) Hydraulic Station for QT4-18 Block Machine line

The electromagnetic valve is a unique proportional valve multi-channel control system, all-round adjustment of any action, so that the machine is running more reliable and

sensitive, it is made from Taiwan CYLCA brand.

(6) Model: Blocks Conveyor Machine for QT4-18 Block Making Machine

Power: 1.1KW

Function: after blocks are are made, this block conveyor will transport the blocks out from block machine, to the block stacking section.

(6) Model: Blocks Conveyor Machine for QT4-18 Block Making Machine

Power: 1.1KW

Function: after blocks are are made, this block conveyor will transport the blocks out from block machine, to the block stacking section.

(7) Single Block Pallets Stacking Machine for QT4-18 Block Machine

Power: 3.0KW

Function: to Stack the finished blocks to several layers, make blocks are ready for transport by forklift or manual trolley.

The client can also choose double pallets stacking machine to replace the single pallet stacking machine here.

(7) Single Block Pallets Stacking Machine for QT4-18 Block Machine

Power: 3.0KW

Function: to Stack the finished blocks to several layers, make blocks are ready for transport by forklift or manual trolley.

The client can also choose double pallets stacking machine to replace the single pallet stacking machine here.  (8) Manual Trolley for QT4-18 Block Machine Line

Function: transport the produced blocks to curing area; there are two sets with the stacking machine. Client can also buy diesel forklift or electric forklift to save labor in this procedure; RAYTONE block machine factory has electric forklift dedicated for block factory use. (9) JQ350 Pigment Pan Mixer for QT4-18 Block Making Machine Line

Diameter: 1.2M;

Power: 7.5-4KW or 5.5-6KW

Input Capacity: 500L

Output Capacity:350L

Size:1.2(L)*1.2(W)*1.4(H)m

Weight: 550kg

Barrel height: 50cm

Barrel thickness: 8mm

Bottom thickness: 7mm

This is used for mixing the pigments with white cement.

(8) Manual Trolley for QT4-18 Block Machine Line

Function: transport the produced blocks to curing area; there are two sets with the stacking machine. Client can also buy diesel forklift or electric forklift to save labor in this procedure; RAYTONE block machine factory has electric forklift dedicated for block factory use. (9) JQ350 Pigment Pan Mixer for QT4-18 Block Making Machine Line

Diameter: 1.2M;

Power: 7.5-4KW or 5.5-6KW

Input Capacity: 500L

Output Capacity:350L

Size:1.2(L)*1.2(W)*1.4(H)m

Weight: 550kg

Barrel height: 50cm

Barrel thickness: 8mm

Bottom thickness: 7mm

This is used for mixing the pigments with white cement.

(10) Brick Face Pigments feeding Machine for QT4-18 Block Making Machine

Function: used to feed pigments onto the paver bricks surface.

This part is optional, the client who makes paver bricks with color can buy this machine.

(10) Brick Face Pigments feeding Machine for QT4-18 Block Making Machine

Function: used to feed pigments onto the paver bricks surface.

This part is optional, the client who makes paver bricks with color can buy this machine.

(11) Brick Pallet Loading Machine for QT4-18 Block Making Machine Line

Power: 5.2KW;

Function: this brick pallet loader is used to load the brick pallets into Pallet Feeder of brick machine, can save a worker here.

(11) Brick Pallet Loading Machine for QT4-18 Block Making Machine Line

Power: 5.2KW;

Function: this brick pallet loader is used to load the brick pallets into Pallet Feeder of brick machine, can save a worker here.

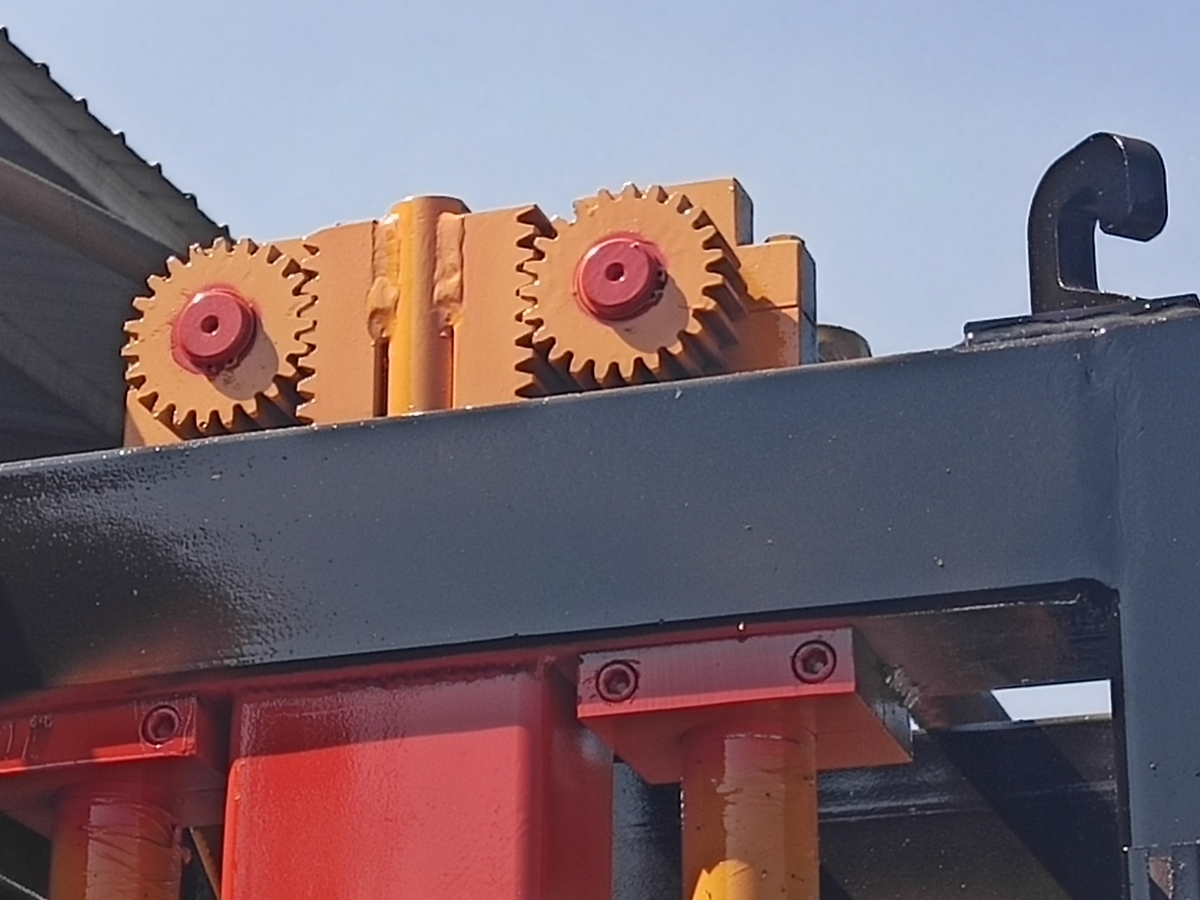

(12) Model: GMT brick pallets supported for QT4-18 brick machine

Life: 8 years

Density: 1200kg/Cubic meters

GMT pallet is the most popular and cost to performance pallet now.

Pallet size: 880*550*22mm

(12) Model: GMT brick pallets supported for QT4-18 brick machine

Life: 8 years

Density: 1200kg/Cubic meters

GMT pallet is the most popular and cost to performance pallet now.

Pallet size: 880*550*22mm

(13) Spare parts for QT4-18 block machine line

RAYTONE block machine factory provides tools, easy wearing parts such as pliers, screwdrivers, springs, bolts and nuts, sensors, triangle belts, etc

(13) Spare parts for QT4-18 block machine line

RAYTONE block machine factory provides tools, easy wearing parts such as pliers, screwdrivers, springs, bolts and nuts, sensors, triangle belts, etc

Capacity of different blocks models under QT4-18 Block Making Machine Different block product from QT4-18 Automatic Block Making Machine

Capacity of different blocks models under QT4-18 Block Making Machine Different block product from QT4-18 Automatic Block Making Machine

Shipping & Packing

We can package the machines according to your requirements. Whether it’s a plywood box or an iron frame, we can use either. Each machine will be wrapped in plastic film

to reduce wear and tear. Our on-time delivery rate is 100%.

Shipping & Packing

We can package the machines according to your requirements. Whether it’s a plywood box or an iron frame, we can use either. Each machine will be wrapped in plastic film

to reduce wear and tear. Our on-time delivery rate is 100%.

The basic requirements for starting the production of the QT4-18 automatic brick-making machine production line:

The following information for the QT4-18 brick-making machine is provided for reference only. The actual production data in the field may vary due to factors such as

different raw materials.

The basic requirements for starting the production of the QT4-18 automatic brick-making machine production line:

The following information for the QT4-18 brick-making machine is provided for reference only. The actual production data in the field may vary due to factors such as

different raw materials.

| Area of land | 1200 sqm | Water consumption | 4 t/day |

| Workshop area | 100 sqm | Voltage and frequency | 220V / 380V / 415V;50HZ / 60HZ |

| Wokers | 6 workers | Consumption | 35.85KW*8 hours = 286.8KWH; |

| Cement consumption | 10.5 t/day | Sand consumption | 42 t/day |

| Quarry stone consumption | 52 t/day |

| 1 | JQ500 Pan Mixer | 1 set | 8 | JQ350 pigment mixer | 1 set |

| 2 | 6M Belt Conveyor | 1 set | 9 | Pigments Feeding Machine | 1 set |

| 3 | Rick Pallet Feeder | 1 set | 10 | Blocks Stacking Machines | 1 set |

| 4 | QT4-18 Host Brick Making Machine | 1 set | 11 | Manual trolleys | 1 set |

| 5 | PLC Control Panel | 1 set | 12 | Brick Pallet Loading Machine | 1 set |

| 6 | Hydraulic Station | 1 set | 13 | GMT Pallets | 1000 pcs |

| 7 | Block Conveyor Machine | 1 set | 14 | Spare Parts | 1 set |

Detailed Introduction of each single machine from QT4-18 Automatic Concrete Block Machine Line (1) Concrete Mixer for QT4-18 brick machine line

Model: JQ500 Concrete Mixer

Power: 11KW-4 or 7.5KW-6

Input Capacity: 800L

Output Capacity:500L

Size:1.5(L)*1.5(W)*1.4(H)m

Weight: 750kg

Barrel height: 60cm

Barrel thickness: 8mm

Bottom thickness: 7mm

Detailed Introduction of each single machine from QT4-18 Automatic Concrete Block Machine Line (1) Concrete Mixer for QT4-18 brick machine line

Model: JQ500 Concrete Mixer

Power: 11KW-4 or 7.5KW-6

Input Capacity: 800L

Output Capacity:500L

Size:1.5(L)*1.5(W)*1.4(H)m

Weight: 750kg

Barrel height: 60cm

Barrel thickness: 8mm

Bottom thickness: 7mm

(2) Belt Conveying Machine for QT4-18 Brick Making Machine line

Model: 6M Belt Conveyor

Power: 1.5KW

Belt Width: 500mm

Weight:550kg

Client can also choose 8 Meters length for the block machine as per land area. RAYTONE block machine manufacture is using chain type rotating system instead of triangle belts for rotating the belts. It has long life and easy to maintain.

(2) Belt Conveying Machine for QT4-18 Brick Making Machine line

Model: 6M Belt Conveyor

Power: 1.5KW

Belt Width: 500mm

Weight:550kg

Client can also choose 8 Meters length for the block machine as per land area. RAYTONE block machine manufacture is using chain type rotating system instead of triangle belts for rotating the belts. It has long life and easy to maintain.  (3)Brick Pallet Feeding Machine

For QT4-18 Brick Making line. Brick Pallet Feeder Connected with host brick machine; RAYTONE block machine manufacture modified this feeding machine by making it to be a long steel plate to push the pallet, instead of two hooks at two ends, this can protect the brick pallet from damage (4)Model: QT4-18 Host Brick Machine

Size:3740(L)×2250(W)×2450(H)mm

Machine Weight:4000kg

host brick Machine power: 25KW

Motors power List:

① Hydraulic Station Motor: 11 KW

② Vibrator Motor: 5.5KW*2=11KW

③ Material Discharge Motor: 1.5KW

④ Material Distributor Motor: 1.5KW

Moulding Period 15-20 S

Vibration Force: 50-65KN

Diesel Generator Capacity: 50KVA

RAYTONE block machine manufacture is using 11KW motor for hydraulic station instead of the normal 7.5KW motor, this gives the bricks more pressure on pressing.

(3)Brick Pallet Feeding Machine

For QT4-18 Brick Making line. Brick Pallet Feeder Connected with host brick machine; RAYTONE block machine manufacture modified this feeding machine by making it to be a long steel plate to push the pallet, instead of two hooks at two ends, this can protect the brick pallet from damage (4)Model: QT4-18 Host Brick Machine

Size:3740(L)×2250(W)×2450(H)mm

Machine Weight:4000kg

host brick Machine power: 25KW

Motors power List:

① Hydraulic Station Motor: 11 KW

② Vibrator Motor: 5.5KW*2=11KW

③ Material Discharge Motor: 1.5KW

④ Material Distributor Motor: 1.5KW

Moulding Period 15-20 S

Vibration Force: 50-65KN

Diesel Generator Capacity: 50KVA

RAYTONE block machine manufacture is using 11KW motor for hydraulic station instead of the normal 7.5KW motor, this gives the bricks more pressure on pressing.  (5) PLC for QT4-18 Block Making Machine

PLC is an advanced microcomputer system, Automatic fault diagnosis, procedure is interlocked, can ensure every motion of the block machine fluently and in high efficiency.

The Siemens brand PLC and touch screen is optional. The Electrical panel is using Schneider breaker and China top brand electronic elements like Delixi or CHNT

brand electromagnetic switch as standard configuration, , having a reliable performance and low fault rate. We also equipped the frequency converter to make the electronic parts work at a safe condition.The setting of every machine motion can be done via the touch screen, perfect human-machine communicating system.

And there is also a standby software as backup.

(5) PLC for QT4-18 Block Making Machine

PLC is an advanced microcomputer system, Automatic fault diagnosis, procedure is interlocked, can ensure every motion of the block machine fluently and in high efficiency.

The Siemens brand PLC and touch screen is optional. The Electrical panel is using Schneider breaker and China top brand electronic elements like Delixi or CHNT

brand electromagnetic switch as standard configuration, , having a reliable performance and low fault rate. We also equipped the frequency converter to make the electronic parts work at a safe condition.The setting of every machine motion can be done via the touch screen, perfect human-machine communicating system.

And there is also a standby software as backup.

(6) Hydraulic Station for QT4-18 Block Machine line

The electromagnetic valve is a unique proportional valve multi-channel control system, all-round adjustment of any action, so that the machine is running more reliable and

sensitive, it is made from Taiwan CYLCA brand.

(6) Hydraulic Station for QT4-18 Block Machine line

The electromagnetic valve is a unique proportional valve multi-channel control system, all-round adjustment of any action, so that the machine is running more reliable and

sensitive, it is made from Taiwan CYLCA brand.

(6) Model: Blocks Conveyor Machine for QT4-18 Block Making Machine

Power: 1.1KW

Function: after blocks are are made, this block conveyor will transport the blocks out from block machine, to the block stacking section.

(6) Model: Blocks Conveyor Machine for QT4-18 Block Making Machine

Power: 1.1KW

Function: after blocks are are made, this block conveyor will transport the blocks out from block machine, to the block stacking section.

(7) Single Block Pallets Stacking Machine for QT4-18 Block Machine

Power: 3.0KW

Function: to Stack the finished blocks to several layers, make blocks are ready for transport by forklift or manual trolley.

The client can also choose double pallets stacking machine to replace the single pallet stacking machine here.

(7) Single Block Pallets Stacking Machine for QT4-18 Block Machine

Power: 3.0KW

Function: to Stack the finished blocks to several layers, make blocks are ready for transport by forklift or manual trolley.

The client can also choose double pallets stacking machine to replace the single pallet stacking machine here.  (8) Manual Trolley for QT4-18 Block Machine Line

Function: transport the produced blocks to curing area; there are two sets with the stacking machine. Client can also buy diesel forklift or electric forklift to save labor in this procedure; RAYTONE block machine factory has electric forklift dedicated for block factory use. (9) JQ350 Pigment Pan Mixer for QT4-18 Block Making Machine Line

Diameter: 1.2M;

Power: 7.5-4KW or 5.5-6KW

Input Capacity: 500L

Output Capacity:350L

Size:1.2(L)*1.2(W)*1.4(H)m

Weight: 550kg

Barrel height: 50cm

Barrel thickness: 8mm

Bottom thickness: 7mm

This is used for mixing the pigments with white cement.

(8) Manual Trolley for QT4-18 Block Machine Line

Function: transport the produced blocks to curing area; there are two sets with the stacking machine. Client can also buy diesel forklift or electric forklift to save labor in this procedure; RAYTONE block machine factory has electric forklift dedicated for block factory use. (9) JQ350 Pigment Pan Mixer for QT4-18 Block Making Machine Line

Diameter: 1.2M;

Power: 7.5-4KW or 5.5-6KW

Input Capacity: 500L

Output Capacity:350L

Size:1.2(L)*1.2(W)*1.4(H)m

Weight: 550kg

Barrel height: 50cm

Barrel thickness: 8mm

Bottom thickness: 7mm

This is used for mixing the pigments with white cement.

(10) Brick Face Pigments feeding Machine for QT4-18 Block Making Machine

Function: used to feed pigments onto the paver bricks surface.

This part is optional, the client who makes paver bricks with color can buy this machine.

(10) Brick Face Pigments feeding Machine for QT4-18 Block Making Machine

Function: used to feed pigments onto the paver bricks surface.

This part is optional, the client who makes paver bricks with color can buy this machine.

(11) Brick Pallet Loading Machine for QT4-18 Block Making Machine Line

Power: 5.2KW;

Function: this brick pallet loader is used to load the brick pallets into Pallet Feeder of brick machine, can save a worker here.

(11) Brick Pallet Loading Machine for QT4-18 Block Making Machine Line

Power: 5.2KW;

Function: this brick pallet loader is used to load the brick pallets into Pallet Feeder of brick machine, can save a worker here.

(12) Model: GMT brick pallets supported for QT4-18 brick machine

Life: 8 years

Density: 1200kg/Cubic meters

GMT pallet is the most popular and cost to performance pallet now.

Pallet size: 880*550*22mm

(12) Model: GMT brick pallets supported for QT4-18 brick machine

Life: 8 years

Density: 1200kg/Cubic meters

GMT pallet is the most popular and cost to performance pallet now.

Pallet size: 880*550*22mm

(13) Spare parts for QT4-18 block machine line

RAYTONE block machine factory provides tools, easy wearing parts such as pliers, screwdrivers, springs, bolts and nuts, sensors, triangle belts, etc

(13) Spare parts for QT4-18 block machine line

RAYTONE block machine factory provides tools, easy wearing parts such as pliers, screwdrivers, springs, bolts and nuts, sensors, triangle belts, etc

Capacity of different blocks models under QT4-18 Block Making Machine

Capacity of different blocks models under QT4-18 Block Making Machine

Shipping & Packing

We can package the machines according to your requirements. Whether it’s a plywood box or an iron frame, we can use either. Each machine will be wrapped in plastic film

to reduce wear and tear. Our on-time delivery rate is 100%.

Shipping & Packing

We can package the machines according to your requirements. Whether it’s a plywood box or an iron frame, we can use either. Each machine will be wrapped in plastic film

to reduce wear and tear. Our on-time delivery rate is 100%.